This article explains flanges and fittings. They are the essential parts that connect pipe sections into a working system. Knowing the difference between them is important for design and maintenance.

Flanges are flat discs with bolt holes. They create connections that can be taken apart with tools. They are used at equipment connections, valves, or where a section of pipe might need removal.

Fittings are connectors that change the direction, branch off, or reduce the size of a pipe run. They are typically welded or threaded into place and form a permanent part of the piping system.

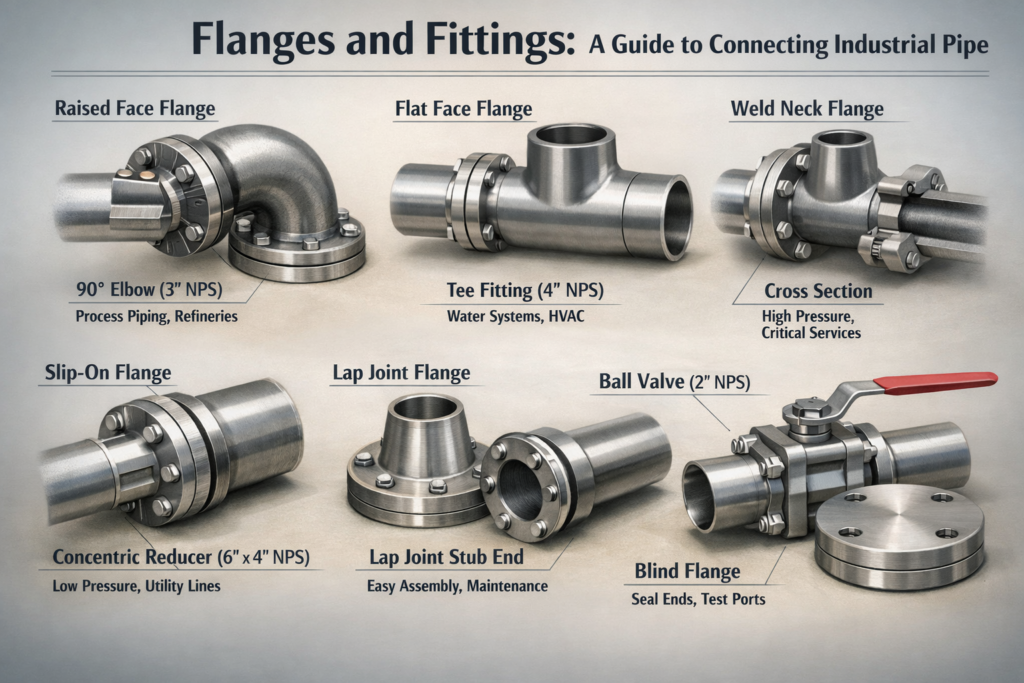

Here is a comparison of their main types and functions.

| Part Type | Main Purpose | Common Types | Connection Method |

| Flanges | Create a bolted, removable connection between pipes, valves, or equipment. | Weld Neck, Slip-On, Blind, Lap Joint, Threaded, Socket Weld. | Bolted together with a gasket. Some types (WN, SO) are welded to the pipe first. |

| Fittings | Permanently change the pipe’s direction, size, or create branches within the system. | Elbows (90°, 45°), Tees, Reducers, Caps, Crosses, Stub Ends. | Welded (Buttweld or Socket Weld) or Threaded. |

Common Flange Types

- Weld Neck (WN): Has a long tapered hub. It is butt-welded to the pipe. Used for high-pressure, high-temperature, or critical service.

- Slip-On (SO): Slides over the pipe and is welded inside and outside. Common for lower-pressure applications. Easier to align.

- Blind (BL): A solid disc with no bore. Used to close off the end of a pipe or valve opening.

- Lap Joint (LJ): Used with a Stub End fitting. The flange rotates freely, making bolt hole alignment easy for systems that need frequent disassembly.

- Threaded: Has internal threads to screw onto a pipe. Used where welding is not possible.

- Socket Weld (SW): Pipe fits into a socket in the flange and is then fillet welded. Good for small-diameter, high-pressure lines.

Common Fitting Types

- Elbows: Change the direction of flow. 90° and 45° angles are standard.

- Tees: Allow flow to be split or combined from a branch line.

- Reducers: Connect two pipes of different diameters. Can be concentric (aligned centers) or eccentric (offset centers).

- Caps: Seal the end of a pipe permanently.

- Stub Ends: Used with Lap Joint flanges. The stub end is welded to the pipe, providing the sealing surface.

Standards, Ratings, and Materials

All flanges and fittings are made to published standards. This ensures parts from different manufacturers fit together.

- Key Standards: The main standard for flanges and buttweld fittings is ASME B16.5 (for NPS 1/2″ to 24″). Large flanges follow ASME B16.47. Other standards include MSS SP-97 for socket weld fittings.

- Pressure Class: Flanges have a class rating like 150, 300, or 600. This is a pressure-temperature rating, not a direct PSI value. A higher class means a thicker, stronger part. Fittings match the pressure class of the flanges they connect to.

- Materials: Parts are made from materials that match the pipe and process fluid. Common ones are Carbon Steel (A105, A234 WPB), Stainless Steel (A182 F304/316), and various Alloy Steels.

How to Specify Flanges and Fittings

To order the correct part, you need to provide specific information:

- Size: Nominal Pipe Size (NPS).

- Pressure Class: 150, 300, etc.

- Type: Weld Neck, Slip-On, 90° Elbow, Tee, etc.

- Material Specification: e.g., ASTM A105.

- Standard: e.g., ASME B16.5.

- Additional Details: For flanges, specify the facing (e.g., Raised Face). For fittings, specify the schedule (wall thickness).

Frequently Asked Questions

Q: Can I mix different flange types in a connection?

A: Yes, as long as they share the same Nominal Pipe Size, Pressure Class, and Bolt Circle. For example, you can bolt a Weld Neck flange to a Blind flange.

Q: What’s the difference between a buttweld fitting and a socket weld fitting?

A: A buttweld fitting has a beveled end for a full-penetration butt weld. It is stronger and used for critical service. A socket weld fitting has a recess (socket) for the pipe to fit into, secured with a fillet weld.

Q: Why use a Lap Joint flange instead of a Slip-On flange?

A: A Lap Joint flange is not welded to the pipe. It allows the flange to rotate, which makes bolt hole alignment much easier. This is ideal for systems that need regular opening for cleaning or inspection.

Q: What are “spectacle blinds” or “line blinds”?

A: These are special safety fittings installed between two flanges. They have a solid section (blind) and a ring section (spacer). Rotating the spectacle blind either blocks flow completely or allows it to pass, providing visible isolation.

Conclusion

Flanges create accessible, bolted connections. Fittings permanently direct and shape the pipe system. Understanding the types, standards, and how to specify them is key to building safe, reliable, and maintainable piping.

Need help selecting the right flanges and fittings for your system’s pressure, temperature, and material requirements? We can provide the correct ASME-standard components for your project.

Submit your specifications for a quote: http://texasflange.com/lp12/